24 April

WORLD CORROSION AWARENESS DAY

„Save the date” is a series of articles that have been written to celebrate various unusual holidays. The authors of the presented materials are students, doctoral students and employees of the Faculty of Science and Technology of the University of Silesia.

In 2010, the World Corrosion Organization (WCO) declared April 24 as World Corrosion Awareness Day. Corrosion is a global problem, and the purpose of World Corrosion Awareness Day is to make the public aware of the dangers that result from corroding materials. According to experts’ estimates, the cost of removing corrosion damage in Poland is about 90 billion zlotys a year. These are not the only costs, as various materials are increasingly being covered with protective coatings against corrosion, and this increases the cost of repairs.

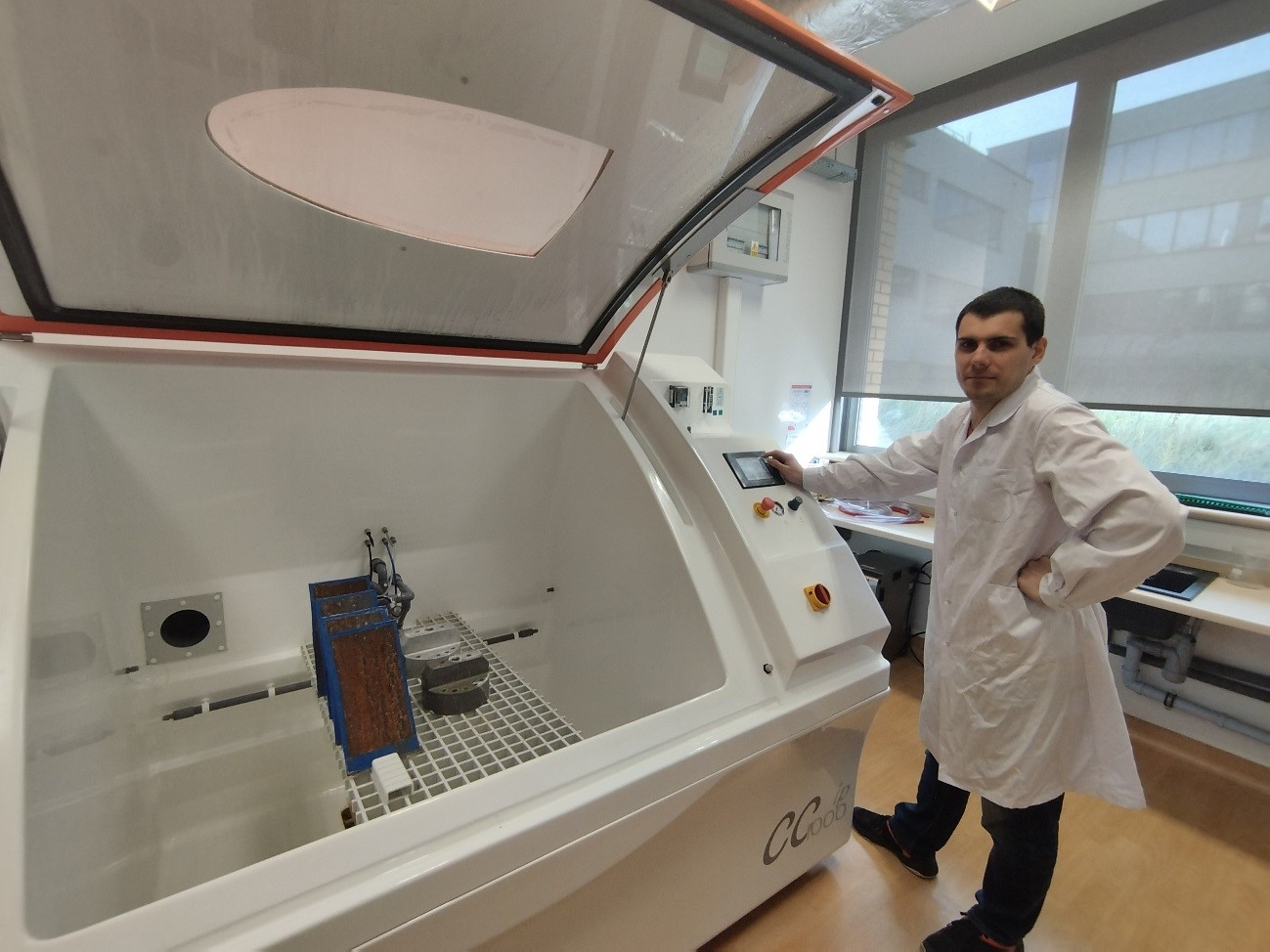

ADRIAN GUDWAŃSKI, PhD

Biuro ds. Infrastruktury Badawczo-Dydaktycznej Wydziału Nauk Ścisłych i Technicznych

- Graduate of the University of Silesia in Katowice. Doctor of exact

and natural sciences in the discipline of chemical sciences. - Specialist in the Corrosion Testing Laboratory located

at the Institute of Materials Engineering, Faculty of Science and Technology, University of Silesia in Katowice. He cooperates with many branches of industry by conducting accelerated corrosion tests in salt chambers.

Research interests: organic and inorganic chemistry, research on corrosion resistance of materials (metals and their alloys, composites, anodic and cathodic metal coatings, conversion coatings, anodic oxide coatings, organic coatings on metal materials). - Hobby: sports (especially football), history, exact science

Corrosion is not entirely a “down-to-earth” issue… or the role of corrosion in plane crashes

On 24 April, we celebrate World Corrosion Awareness Day.

Despite the technological development and the emergence of newer and better methods of protection against corrosion, we are still unable to eliminate it once and for all. According to calculations, 25 million tons of steel are destroyed by corrosion every year on a global scale, and the global annual cost of related losses is estimated at 2.5 trillion dollars. The problem of corrosion affects virtually all areas of infrastructure, including construction, automotive, aviation, maritime, chemical and oil industries. In addition to material and financial losses, corrosion may also lead, directly or indirectly, to more tragic events – loss of human health and/or life. This article presents examples of plane crashes in which corrosion played a role.

MiG-23M plane crash near Kortrijk (4 July 1989)

source: https://www.smartage.pl/wp-content/uploads/2021/10/3555-1080×516.jpg

On 4 July 1989, a Soviet MiG-23M plane with tail number 29, piloted by a Soviet pilot, Colonel Nikolai Skuridin, crashed in the Belgian city of Kortrijk. On the fateful day, the plane took off from the Bagicz military airport in Kołobrzeg at 9.14 a.m., heading towards the Baltic Sea. After the plane took off, at an altitude of 100-150 metres, the pilot turned on the afterburner to increase engine thrust, but this seemed to have caused the engine speed to drop significantly, causing a reduction in power and a loss of speed. Realising that, the pilot concluded that the engine was damaged or turned off and he catapulted himself out of the machine, landing safely in the sea, from where he was rescued by a helicopter. However, the plane continued to fly for about 900 km, passing over several European countries, and finally crashed only after running out of fuel in the city of Kortrijk at around 10.37 a.m. local time. As a result of the disaster, one person died – a resident of Kortrijk.

The first question that arises in such circumstances is how it is possible that a plane with a faulty engine flew such a long distance instead of crashing? The investigation conducted after the disaster showed that the engine was not completely damaged, but due to electrochemical corrosion of one of the elements of the electrical system (resulting from the engine wires being constantly exposed to sea water), its power temporarily decreased. After the pilot ejected himself, the engine speed was increased to the maximum value, which caused the plane to climb to an altitude of 12,300 metres, and the activated system controlling the flight parameters (autopilot) with which the plane was equipped kept the machine in the air on the designated course and altitude until it ran out of fuel and crashed.

KC-130T crash (10 July 2017)

source: https://i.dailymail.co.uk/i/pix/2017/07/11/16/42389AF200000578-4683912-image-a-16_1499785203087.jpg

On 10 July 2017, at 3.49 p.m. local time (10.49 p.m. Polish time) a Lockheed Martin KC-130 plane belonging to the American armed forces, transporting ammunition and military vehicles, crashed near the city of Greenwood, Mississippi. The cause of the disaster was considered to be the detachment of the propeller blade which subsequently impacted the fuselage at an altitude of approximately 6,100 metres. As a result of this impact, a series of failures occurred: detachment of part of the plating, overload of the drive shaft of engine No. 3, detachment of the propeller from this engine and its penetration into the fuselage of the aircraft, and impact on the horizontal stabiliser and detachment of its parts. The consequence of these events was that the plane’s fuselage first broke down into three parts due to decompression, and then continued to disintegrate into even smaller parts. 16 people died in the disaster. As a result of the investigation, it was determined that out of 16 propeller blades powering the plane, 12 of them had traces of deep corrosion (pitting corrosion). As it turned out, these traces were present even before the technical regeneration process carried out in 2011 (the process is carried out after 5,000 hours of operation). The most interesting fact is that all propellers passed the quality control stage without any irregularities. So how is it possible that signs of corrosion were not noticed before the regeneration process began? Possible reasons include, for example:

- probable failure to perform eddy current tests on the blades during the initial defectoscopic tests, which resulted in missing the traces of corrosion on the propeller blades (such tests are required by the Navy and Marine Corps),

- no traces of anti-corrosion epoxy coatings were detected on propeller blades (also required by the Navy and Marine Corps),

- procedures allowing the removal of documentation regarding the blade inspection two years after it was carried out, which at the same time made it impossible to later find answers to questions about who and how performed the service work, whether protective coatings were applied (if so, when and how) and whether the execution of service work has been confirmed (if so, who and when confirmed it).

After the disaster, a team was established to develop recommendations and procedures to prevent similar mistakes from being repeated in the future.

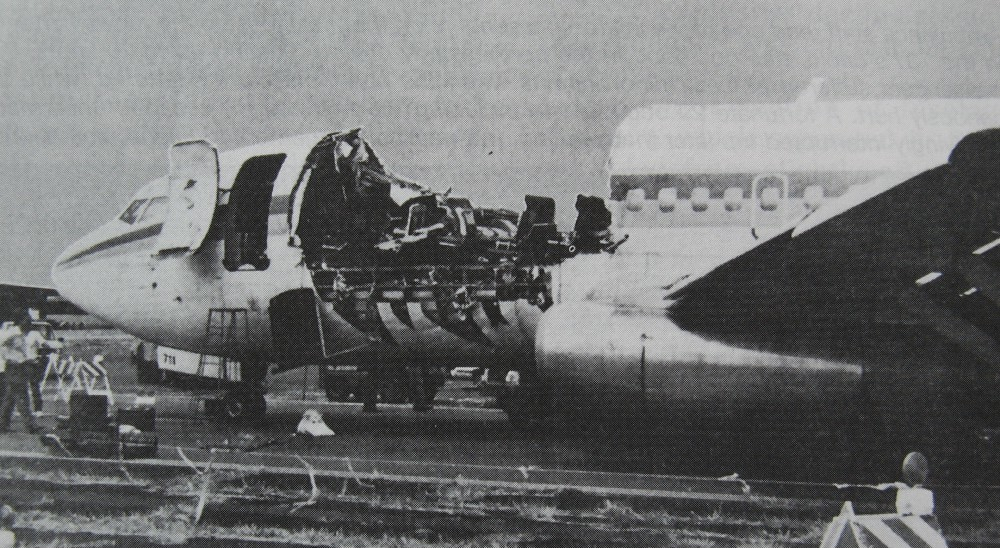

Katastrofa lotu Aloha Airlines 243 (28 kwietnia 1988 r.)

On 28 April 1988, a damaged Aloha Airlines Boeing 737-297 aircraft with tail number N73711, flying from Hilo Airport to Honolulu, landed at Kahului Airport on the island of Maui, Hawaii. As a result of the damage to the plane, 65 people were injured and 1 person died. At approximately 1.48 p.m. local time (12.48 a.m. Polish time), at an altitude of 7,300 metres and approximately 43 km from Kahulu, passengers in the front seats of the aircraft heard a noise coming from the upper part of the fuselage and also observed a crack in the plating. As a result of its rapid expansion, explosive decompression occurred, causing the detachment of a large fragment of the plating (approximately 5-6 metres long). As a result of this, the crew was forced to first quickly descend to a height enabling breathing with atmospheric air (due to the fact that as a result of the detachment of the fuselage plating, some of the passengers were deprived of their oxygen masks), and then to make an emergency landing, which was successfully archived at 1.58 p.m. local time (12.58 a.m. Polish time). The crew managed to land even though the left engine stopped working during the rapid descent, and the pilots were not sure about the state of the landing gear extension.

As a result of an investigation conducted by the National Transportation Safety Board (NTSB), material fatigue combined with corrosion of the aircraft frame (crevice corrosion) was identified as the direct cause of the crash. Corrosion was caused by the high humidity in the Hawaiian area where the aircraft had been flying frequently for almost 20 years. Additionally, the investigation has shown that the crack in the plating was much smaller at the beginning, but the pulling of one of the stewardesses into the crack (who was directly under it) caused it to be blocked and prevented pressure equalization, which consequently led to the detachment of a larger part of the plating. During the investigation, it also came to light that one of the passengers, when boarding the plane, was an eyewitness to the presence of a crack in the fuselage, but for unknown reasons they did not inform any of the crew about this fact.

Katastrofa lotu Far Eastern Air Transport 103 (22 sierpnia 1981 r.)

On 22 August 1981, a Boeing 737-222 aircraft number B-2603 belonging to the Taiwanese airline Far Eastern Air Transport (FEAT) crashed. Shortly after taking off from the airport in Taipei, Taiwan, the plane broke into three pieces in the air and then crashed at 10.00 a.m. local time (4.00 a.m. Polish time) near the city of Miaoli (also in Taiwan) killing 110 people.

At the beginning of the investigation, the possibility that the plane had been the target of a terrorist attack was considered, but this hypothesis was quickly dropped when new information came to light. It turned out that during the flight, which took place 17 days before the disaster, the fuselage decompressed due to corrosion. In this case, the pilot managed to turn the plane around and land at the airport, preventing a tragedy. The plane was fixed (corroded parts were repaired), and then returned to service. Unfortunately, on 22 August 1981, the crack increased in size, leading to decompression and, consequently, to the complete disintegration of the plane’s fuselage during the flight and its subsequent collision with the ground.

Ultimately, the probable cause of the disaster was considered to be significant local corrosion damage occurring in the lower parts of the fuselage (resulting from intergranular corrosion as well as exfoliation corrosion) and the presence of previously undetected cracks.

Conclusion

As can be seen from the above-mentioned plane crashes, corrosion is still a serious problem, despite the great progress that has been made over the years regarding corrosion protection. If we additionally take into account the fact that, according to data from the global travel data provider OAG (Official Aviation Guide of the Airways), there have been over 8 million flights around the world since the beginning of 2024 and each of the aircraft flying was exposed to failures caused by corrosion, the issue of anti-corrosion protection of aircraft is extremely important. Of course, corrosion is not the only adversity that the aviation industry has to deal with,as it was not involved in most disasters. However, we must take into account that corrosion is a very real danger, we must understand it and be aware of its presence not only in aviation and not only today on World Corrosion Awareness Day

Źródło:

[1] https://www.chemiaibiznes.com.pl/artykuly/naukowcy-lukasiewicz-maja-patent-na-korozje (data dostępu: 25.03.2024)

[2] https://www.products.pcc.eu/pl/academy/korozja-metali-i-sposoby-jej-zapobiegania/ (data dostępu: 25.03.2024)

[3] https://spidersweb.pl/2023/10/niezwykly-lot-samolotu-mig-23.html (data dostępu: 25.03.2024)

[4] https://www.smartage.pl/katastrofa-mig-a-23-pod-kortrijk-1989/ (data dostępu: 25.03.2024)

[5] https://twierdzakolobrzeg.pl/twierdza/bagicz-rogowo-ustronie/285-lotnisko-ukladu-warszawskiego (data dostępu: 25.03.2024)

[6] https://miastokolobrzeg.pl/historia/7032-tragiczny-lot-pod-koniec-zimnej-wojny.html (data dostępu: 25.03.2024)

[7] https://www.warhistoryonline.com/cold-war/mig-23m-farm-crash-1989.html (data dostępu: 25.03.2024)

[8] https://news.usni.org/2018/12/06/marine-corps-corroded-propeller-blade-that-broke-loose-caused-2017-kc-130t-crash (data dostępu: 25.03.2024)

[9] https://defence24.pl/przemysl/wyjasniono-przyczyne-katastrofy-kc-130t-czy-tylko-bledy-w-obsludze (data dostępu: 25.03.2024)

[10] https://www.konflikty.pl/aktualnosci/wiadomosci/katastrofa-kc-130-w-stanie-missisipi/ (data dostępu: 25.03.2024)

[11] https://www.thisdayinaviation.com/tag/aloha-airlines-flight-243/ (data dostępu: 25.03.2024)

[12] https://www.nzherald.co.nz/world/screams-then-silence-the-story-of-flight-243s-miracle-landing/BDV7QVFFX2K23KKZDEOUWZGI54/ (data dostępu: 25.03.2024)

[13] https://podroze.onet.pl/ciekawe/tragiczny-lot-stewardesa-wyssana-z-samolotu-co-wydarzylo-sie-na-hawajach/ndbtpz2 (data dostępu: 25.03.2024)

[14] https://spidersweb.pl/2023/01/aloha-airlines-243.html (data dostępu: 25.03.2024)

[15] https://geekweek.interia.pl/technologia/news-najpowazniejsze-katastrofy-boeinga-737-w-historii-zginelo-ki,nId,5907392 (data dostępu: 25.03.2024)

[16] https://aviation-safety.net/database/record.php?id=19810822-0 (data dostępu: 25.03.2024)

[17] https://www.oag.com/airline-frequency-and-capacity-statistics (data dostępu: 25.03.2024)