| Olimpia Orządała |

Scientists from the Centre for Biomass Energy Research and Education of the University of Silesia in Katowice have developed an innovative certification of solid biofuels. The method of petrographic analysis in reflected light in oil immersion was used for the first time in the world. Thanks to microscopic tests, it is possible to detect solid contaminants in renewable fuels: wood and non-wood pellets and wood and non-wood briquettes. The uniqueness of the PL-US BIO certification, the way of its development and why it is the power plants, and not mines, that should be liquidated first, is discussed by Iwona Jelonek, PhD Dsc, Associate Professor and Zbigniew Jelonek, PhD from the Institute of Earth Sciences, University of Silesia in Katowice.

Certification – what is it?

The concept of certification can be understood as a certain standardisation or quality of a given product – if it meets certain features, it can then be certified. We can distinguish certificates that are mandatory (e.g. required by European Union standards) and optional. The basis for creating certification are various types of standards, such as ISO and PN-EN, which state whether the delivered product actually meets specific quality criteria.

For biofuels, certification is not mandatory. The manufacturers producing, e.g. wood pellets, decide whether they want their products to undergo a certification process in accordance with rigorous guidelines or not.

‘Fuel producers want to offer safe products. If a given fuel is subjected to certification in accordance with applicable standards, e.g. for biofuels, and it meets them, such fuel can be considered harmless to both the environment and the user’ says Zbigniew Jelonek, PhD.

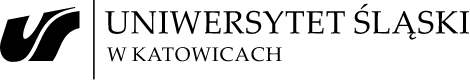

Pellet produced by scientists from the University of Silesia. Composition: 30% hay grass, 70% sawdust, and 3% bran | photo: Olimpia Orządała

Is it worth getting certified? Scientists are unanimous. ‘My answer is simple: do you want to take care of future generations? Do you want to live at least in the same environment that you saw when you were born and took your first breath? This is the moment when we should take care of our Earth for future generations. We can only do this when we have awareness and choice. It is up to us whether we choose certified or uncertified pellets’ says Prof. Iwona Jelonek.

The most popular certificates are the DINplus and ENplus, developed by Italian and German research institutes. Now the group has been joined by PL-US BIO certificate created by scientists from the University of Silesia in Katowice. It was created as a result of many years of research conducted at the Institute of Earth Sciences of the University of Silesia. The researchers decided to develop their own certification method, based on petrographic analysis.

‘Standards set for solid biofuels do not provide for the identification of solid ingredients in these products. However, wood pellets may contain contaminants such as plastics, fossil coals, minerals of various origins (e.g. sand) and glass, which cannot be demonstrated by physicochemical methods in a quantitative and qualitative context. Meanwhile, more than 3% of a given ingredient, e.g. bark in pellets, deteriorates the quality of exhaust gases and causes the formation of sinters and slags in heating installations’ explains Zbigniew Jelonek, PhD.

Contaminants enter biofuels at various stages of production, transport and delivery. Certifications help prevent uncontrolled pollution during the production of solid biofuels. Physicochemical tests determine parameters such as moisture content, ash content, heat of combustion, and also determine the calorific value of the fuel. The certification developed by the University of Silesia team is also based on the optical microscopy method.

Samples with contaminated biofuel. The blue and yellow dots are plastic | photo: Olimpia Orządała

In September 2023, at the 39th meeting of The Society of Organic Petrology (TSOP) and the 74th meeting of the International Committee for Coal and Organic Petrology (ICCP) at the University of Patras in Rio-Patras (Greece), Agnieszka Drobniak, PhS, Dsc Eng. presented the PL-US BIO certification to a panel from around the world.

‘It was a very moving moment, as the world of science could see the potential of our research’ admits prof. Iwona Jelonek.

From charcoal to PL-US BIO certification

It all started with research on charcoal for grill, which was started in 2016 by Zbigniew Jelonek, PhD. Subsequently, scientific work was extended to wood pellets and other types of biomass fuels. The turning points that contributed to the development of certification included, among others, solving problems that occurred during the implementation of doctoral thesis by Adam Nocoń, manufacturer of pellet boilers.

‘The pellet, which had passed all physical and chemical tests and obtained ENplus and DINplus certificates, ‘slagged the boiler’, i.e. it formed sinters on the burner and as a result – the boiler kept turning off. I examined both the pellet and the slag under a microscope, and it turned out that there was too much bark, while the slag contained unburnt pellet fragments. In this way, we began to examine pellets and check how their composition affects both the installation and exhaust emissions during combustion. Even though the pellet underwent physicochemical tests in accordance with the guidelines in the standards, it did not mean that it was good, as it could slag or emit excessive amounts of harmful exhaust gases’ says Zbigniew Jelonek, PhD. ‘We have included petrography in our certification, which complements the existing research and guidelines contained in the standards for fuels produced from biomass and allows us to determine what solid components and in what quantities apart from biomass are included in the pellet.

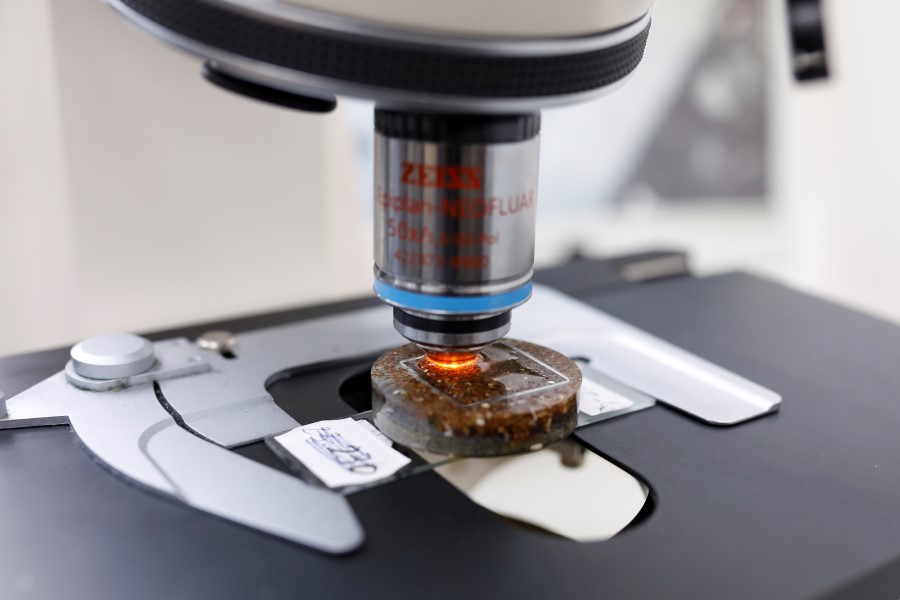

The certification developed at the University of Silesia provides producers with a brand and certifies quality – a certified product should not harm the environment or the installation if the production regime is maintained. It is distinguished by microscopic examination in reflected light in oil immersion – a method that was developed for fossil fuels. It is also worth emphasising that all tests carried out in accordance with the standards on which the certification is based are performed in accredited laboratories.

Testing a pellet sample in reflected white light in oil immersion | photo: Olimpia Orządała

The certification process assesses whether the solid biofuel meets the relevant requirements of the EN ISO 17225 standard in terms of physicochemical and technical parameters. By including the identification of ingredients in accordance with the proprietary classification based on microscopic examination, scientists from the University of Silesia complement the tests provided for in the standard. Importantly, manufacturers receive not only a tabular list of ingredients, but also an interpretation of the results and tips on how to improve the product if it does not meet stringent criteria.

So far, two clients have received the certificates. The information about the quality of their products can be found on the website of the Centre for Biomass Energy Research and Education of the University of Silesia. The certification is addressed to individual users, not to industrial plants. However, scientists are open to cooperation with large corporations.

‘We issue the certificate for one year only. The contract includes a provision that we can take a sample of the product and test it at any stage. We check whether the manufacturer maintains the quality of the fuel without notice. The manufacturer does not know the day or hour of product verification, and we also encourage ‘end’ recipients to send us samples of pellets with our certification mark for verification in case of any reservations regarding the quality of the purchased goods’ explains Zbigniew Jelonek, PhD. ‘At the moment, no certifying institution uses this type of confirmation of product quality.

If a defect is found, the manufacturer’s consent to use the PL-US BIO certificate mark is automatically withdrawn.

Interestingly, the University of Silesia does not have exclusive rights to the developed certification. Researchers from the centre encourage laboratories to cooperate, ensuring appropriate training and providing the certification method. Scientists have carefully developed a classification and prepared a catalog of patterns on how to identify solid components in pellets that should not be present in this fuel if we want to ensure air quality. The contaminants catalog is available in open access form on the website of Indiana University Bloomington.

‘We have devoted part of our life and experience to develop a method that will be repeatable and widely available. Nothing stops you from starting cooperation with us’ says prof. Iwona Jelonek.

Before the certification was introduced, an international exercise led by Agnieszka Drobniak, PhD, DSc, Eng. was organised to develop and confirm the repeatability of the obtained results. Dozens of laboratories and petrographers from several countries took part in it.

Scientists from the University of Silesia recently submitted an application to the Polish Committee for Standardisation, proposing a standard based on multi-faceted research, thanks to which the PL-US BIO certification was created. If the standard is accepted, it will then become mandatory for all those who decide to become certified. The researchers are also trying to obtain a grant from the National Science Centre for further work.

Scientists’ workplace | photo: Olimpia Orządała

There is no decarbonisation without carbonisation

The world is experiencing a leap in energy transition as it moves towards the Green Deal. Most countries are aiming to reduce coal extraction and close down coal mines. However, scientists from the University of Silesia emphasise that 50 million tons of this raw material are still burned in Europe, not only in Poland, although our country is the leader. The complete opposite is China, where its extraction has increased by 20% and new mines are being opened.

Researchers point out that a replacement for coal for our energy needs will not be created overnight, but over time solid biofuels may turn out to be a substitute and therefore it is worth taking care of their quality now through product certification. This will reduce low emissions, i.e. the emission of harmful dust and gases occurring at a height of up to 40 meters.

‘Fossil fuels, which were created hundreds of millions of years ago, ‘inhaled’ CO₂ and other gases. When we extract and thermally transform these fuels, they give this charge back. We then release unfavourable CO₂ emissions into the atmosphere. Biofuels, on the other hand, are zero-emission because their source is both annual and perennial plants. During a year or throughout their long-term vegetation, they absorb as much as they can and then release carbon dioxide into the atmosphere. An example is a pellet made from hay as a one-year-old and a pellet made from wood as a long-term CO2 assimilator’ explains prof. Iwona Jelonek.

‘Coal did not ask for the world to be brought into the world. The Romans already used fossil fuel 2,000 years ago. And what about the man who reached for the fire, lighting a piece of wood? Did he think about your carbon footprint back then? We used coal in the industrial revolution and we continue to use it. And now we push it out of our lives and ruin his reputation. Let’s wake up! and let’s not get crazy. I am often seen as a fossil fuel lobbyist. The truth is I just have some awareness. We have to move away from coal and there is no way back, but let’s do it sensibly, in a well-thought-out way’ says prof. Iwona Jelonek.

‘We should start by closing down coal-fired power plants, not mines. First, let’s replace them with other energy sources, as, for example, Germany did. At the beginning, they gradually replaced coal-fired power plants with photovoltaics and nuclear power plants, and only later closed the mines. Several of them are still in operation as needed for active installations’ emphasises Zbigniew Jelonek, PhD.

‘There is no decarbonisation without carbonisation. We still need coal for everything we need to produce in order to move away from fossil fuels. I really dream about it and believe that Silesia will be a beautiful green island where we will not forget about our post-mining heritage. Let’s open our eyes and talk about the fact that the climate is warming and the Earth is at a crossroads. But let’s not be extreme. Let’s not arm undemocratic countries by bringing this raw material to Poland and Europe. Let’s carry out this transformation in a thoughtful way’ sums up prof. Iwona Jelonek.

Detailed information about the PL-US BIO certification, including a description of the procedure for obtaining the certificate can be found on the Centre for Biomass Energy Research and Education University of Silesia website.

Iwona Jelonek, PhD, DSc, Associat Professor and Zbigniew Jelonek, phD from the Institute of Earth Sciences at the University of Silesia in Katowice | photo: Olimpia Orządała